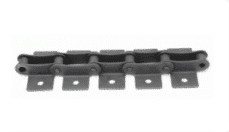

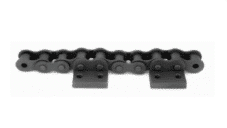

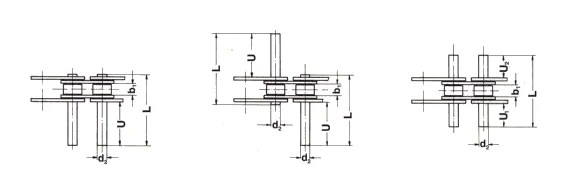

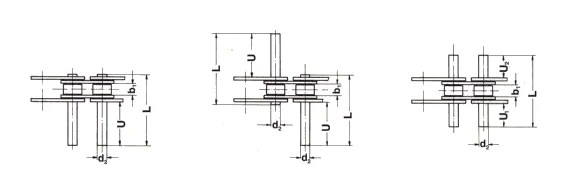

Extended pins

Roller chains with standardized extended pins give designers in plant and mechanical engineering many options for their own designs. The standardized extended pins (to ISO 606) serve as an interface for attaching individual, functional attachments to roller chains. In addition, customized pins can be applied to all chains without great difficulty.

Advantages of roller chains with extended pins

- Mounting on one or both sides possible

- Any pitch spacing possible

- Chains with duplex and triplex pins standardized to ISO 606

- Grooving possible for closing springs, Seeger or E-rings

- Holes for split pins or wire pins possible

- Various pin diameters possible

- Special shapes according to drawing possible

- Mounting on siplex, duplex and triplex chains possible

- Wide range of applications as drive, conveyor and lifting chains

- Fulfillment of versatile functions with attachments for special chains

- Robustness against temperature influences and soiling

- Positive transmission without slippage

- Economic efficiency

- Wide range of chain sizes as well as single and multiple chains

- Versatile transmission ratios

- Large shaft spacing can be realized, e.g. in conveyor systems

- Announcement of the service life limit through chain elongation

- Easy lengthening and shortening

- Drive and output possible on both sides

- No preload = no static bearing load

- Fire safety

- also available in galvanized, nickel-plated, stainless steel

If the range of standardized extended pins is not sufficient, pins can be manufactured quickly and individually according to customer requirements.

Extended pins – dimension table

The table contains our standard drive pins; these can be supplied in the dimensions d2, L, U, U1 and U2 can be varied.

The outer contours can be customized according to your wishes.

| Roller chains with extended pins | ||||||||

| Order no. | DIN Chain no. |

Trade relations p x b1 |

p | b1 min. |

d2 max. |

U Pin spacing one-sided |

U1 = U2 Pin protrusion on both sides |

L max. |

| 08 B-1/2B | 08 B-1 | 1/2" x 5/16" | 12,7 | 7,75 | 4,45 | 15 | 7,9 | 31 |

| 08 B-1/3B | 08 B-1 | 1/2" x 5/16" | 12,7 | 7,75 | 4,45 | 29,2 | 15 | 45,5 |

| 10 B-1/2B | 10 B-1 | 5/8" x 3/8" | 15,88 | 9,65 | 5,08 | 17,6 | 9,3 | 35,5 |

| 10 B-1/3B | 10 B-1 | 5/8" x 3/8" | 15,88 | 9,65 | 5,08 | 34,2 | 17,6 | 52,2 |

| 12 B-1/2B | 12 B-1 | 3/4" x 7/16" | 19,05 | 11,68 | 5,72 | 20,6 | 10,9 | 41,7 |

| 12 B-1/3B | 12 B-1 | 3/4" x 7/16" | 19,05 | 11,68 | 5,72 | 40,1 | 20,7 | 61,3 |

| 16 B-1/2B | 16 B-1 | 1" x 0,67" | 25,4 | 17,02 | 8,28 | 33,5 | 17,6 | 67,4 |

| 16 B-1/3B | 16 B-1 | 1" x 0,67" | 25,4 | 17,02 | 8,28 | 65,4 | 33,6 | 99,3 |

| 20 B-1/2B | 20 B-1 | 1 1/4" x 3/4" | 31,75 | 19,56 | 10,2 | 38,2 | 20 | 78,9 |

| 20 B-1/3B | 20 B-1 | 1 1/4" x 3/4" | 31,75 | 19,56 | 10,2 | 74,2 | 38,3 | 113,4 |

| 40/2B | 40 | 2 1/2" x 1 1/2" | 12,7 | 7,85 | 3,96 | 15,2 | 8 | 30,7 |

| 40/3B | 40 | 2 1/2" x 1 1/2" | 12,7 | 7,85 | 3,96 | 29,6 | 15,2 | 45,1 |

| 50/2B | 50 | 5/8" x 3/8" | 15,88 | 9,4 | 5,08 | 19,2 | 10,1 | 38,5 |

| 50/3B | 50 | 5/8" x 3/8" | 15,88 | 9,4 | 5,08 | 37,3 | 19,1 | 56,7 |

| 60/2B | 60 | 3/4" x 1/2" | 19,05 | 12,57 | 5,94 | 24 | 12,6 | 48,5 |

| 60/3B | 60 | 3/4" x 1/2" | 19,05 | 12,57 | 5,94 | 46,8 | 24 | 71,4 |

| 80/2B | 80 | 1" x 5/8" | 25,4 | 15,75 | 7,92 | 30,9 | 16,3 | 62,4 |

| 80/3B | 80 | 1" x 5/8" | 25,4 | 15,75 | 7,92 | 60,2 | 31 | 91,7 |

| 100/2B | 100 | 1 1/4" x 3/4" | 31,75 | 18,9 | 9,53 | 37,6 | 19,7 | 75,8 |

| 100/3B | 100 | 1 1/4" x 3/4" | 31,75 | 18,9 | 9,53 | 73,4 | 37,6 | 111,6 |

| 208B/2B | 208B | 1" x 1 5/16" | 25,4 | 7,75 | 4,45 | 15,2 | 8,1 | 31 |

| 208B/3B | 208B | 1" x 1 5/16" | 25,4 | 7,75 | 4,45 | 29,2 | 15,1 | 45 |

| 210B/2B | 210B | 1 1/4" x 3/8" | 31,75 | 9,65 | 5,08 | 17,9 | 9,5 | 36 |

| 210B/3B | 210B | 1 1/4" x 3/8" | 31,75 | 9,65 | 5,08 | 15,1 | 17,8 | 52,7 |

| 212B/2B | 212B | 1 1/2" x 7/16" | 38,1 | 11,68 | 5,72 | 20,8 | 11 | 41,8 |

| 212B/3B | 212B | 1 1/2" x 7/16" | 38,1 | 11,68 | 5,72 | 40,3 | 20,7 | 61,3 |

| 216B/2B | 216B | 2" x 0,67" | 50,8 | 17,02 | 8,28 | 33,5 | 17,5 | 67,2 |

| 216B/3B | 216B | 2" x 0,67" | 50,8 | 17,02 | 8,28 | 65,3 | 33,4 | 99 |

| 208A/2B | 208A | 1" x 5/16" | 25,4 | 7,85 | 3,96 | 15,4 | 8,1 | 30,9 |

| 208A/3B | 208A | 1" x 5/16" | 25,4 | 7,85 | 3,96 | 29,7 | 15,3 | 45,2 |

| 210A/2B | 210A | 1 1/4" x 3/8" | 31,75 | 9,4 | 5,08 | 19,2 | 10,1 | 38,7 |

| 210A/3B | 210A | 1 1/4" x 3/8" | 31,75 | 9,4 | 5,08 | 37,3 | 19,2 | 56,8 |

| 212A/2B | 212A | 1 1/2" x 1/2" | 38,1 | 12,57 | 5,94 | 24 | 12,6 | 48,4 |

| 212A/3B | 212A | 1 1/2" x 1/2" | 38,1 | 12,57 | 5,94 | 46,8 | 24 | 71,2 |

| 216A/2B | 216A | 2" x 5/8" | 50,8 | 15,75 | 7,92 | 30,8 | 16,2 | 62 |

| 216A/3B | 216A | 2" x 5/8" | 50,8 | 15,75 | 7,92 | 60,1 | 30,8 | 91,3 |

= Preferred form

Customized according to requirements

Do you need a custom-made product?

Get in touch with us.